- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

The Nanchong Shouchuang Technology Medicinal Drying Machine is designed and produced according to different drying requirements of medicinal materials, with high drying efficiency and good quality of dried products. At the same time, it improves the drying efficiency of medicinal materials and ensures uniform drying of medicinal materials.

The medicinal herb dryer is designed according to the different characteristics of medicinal herbs, such as rhizomes, leaves, fruits, peels, etc. Different product designs are made according to different requirements to meet the drying curve requirements of medicinal herbs, ensuring that the dried medicinal herbs meet the user's requirements.

Components of a medicinal herb dryer: feeding end, drying chamber, discharging end, control system, hot air system

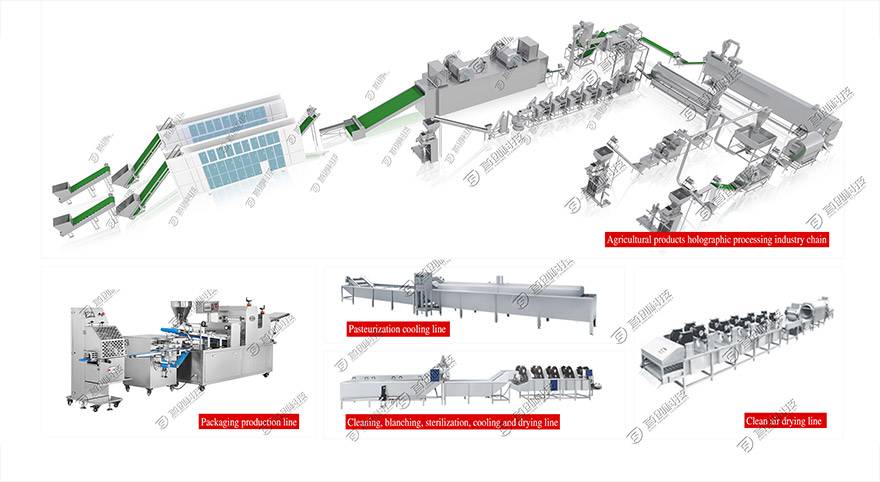

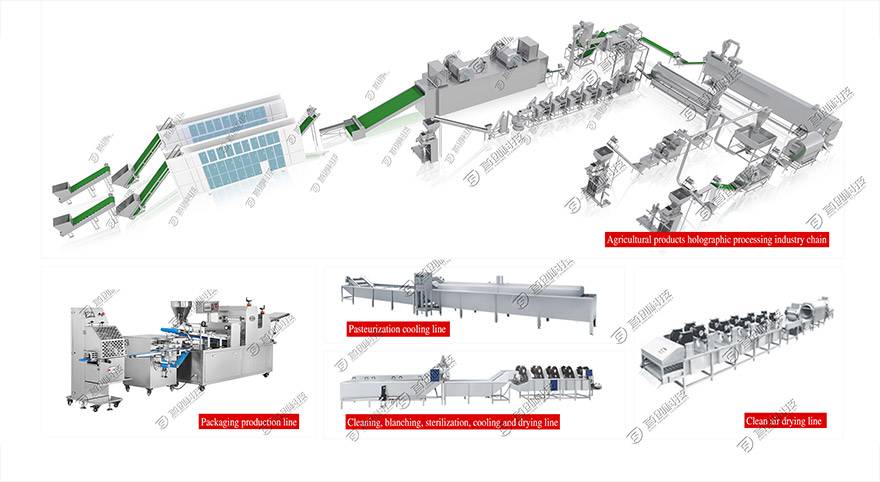

The commonly used medicinal material drying production lines are generally equipped with medicinal material cutting machines, medicinal material conveyors, medicinal material dryers, etc. They can also be equipped with medicinal material sorting machines, medicinal material packaging machines, medicinal material grinding machines, etc. according to different user requirements.

Sichuan Nanchong Shouchuang Technology Development Co., Ltd. was founded in 1972 and is an expert in the field of comprehensive processing equipment for agricultural products. Its core business is the research and development and manufacturing of agricultural product drying equipment, sericulture equipment, air source heat pumps, fans, etc. It covers agricultural product processing, food processing, traditional Chinese medicine material processing, sericulture silk and other fields. The company has established one municipal level enterprise technology center, with nearly 200 employees engaged in research and development, management, sales, and technical work. The production base covers an area of over 50000 square meters.

The company utilizes advanced technology, software, equipment, and services from micro machinery to large-scale complete processing systems to assist in industrial optimization and help customers optimize operations. With continuously enhancing innovation capabilities, outstanding flexible customization capabilities, and perfect delivery capabilities, we have won the trust and cooperation of domestic and foreign customers, and our products are exported to 70 countries and regions around the world.

The Nanchong Shouchuang Technology Medicinal Drying Machine is designed and produced according to different drying requirements of medicinal materials, with high drying efficiency and good quality of dried products. At the same time, it improves the drying efficiency of medicinal materials and ensures uniform drying of medicinal materials.

The medicinal herb dryer is designed according to the different characteristics of medicinal herbs, such as rhizomes, leaves, fruits, peels, etc. Different product designs are made according to different requirements to meet the drying curve requirements of medicinal herbs, ensuring that the dried medicinal herbs meet the user's requirements.

Components of a medicinal herb dryer: feeding end, drying chamber, discharging end, control system, hot air system

The commonly used medicinal material drying production lines are generally equipped with medicinal material cutting machines, medicinal material conveyors, medicinal material dryers, etc. They can also be equipped with medicinal material sorting machines, medicinal material packaging machines, medicinal material grinding machines, etc. according to different user requirements.

Sichuan Nanchong Shouchuang Technology Development Co., Ltd. was founded in 1972 and is an expert in the field of comprehensive processing equipment for agricultural products. Its core business is the research and development and manufacturing of agricultural product drying equipment, sericulture equipment, air source heat pumps, fans, etc. It covers agricultural product processing, food processing, traditional Chinese medicine material processing, sericulture silk and other fields. The company has established one municipal level enterprise technology center, with nearly 200 employees engaged in research and development, management, sales, and technical work. The production base covers an area of over 50000 square meters.

The company utilizes advanced technology, software, equipment, and services from micro machinery to large-scale complete processing systems to assist in industrial optimization and help customers optimize operations. With continuously enhancing innovation capabilities, outstanding flexible customization capabilities, and perfect delivery capabilities, we have won the trust and cooperation of domestic and foreign customers, and our products are exported to 70 countries and regions around the world.