- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

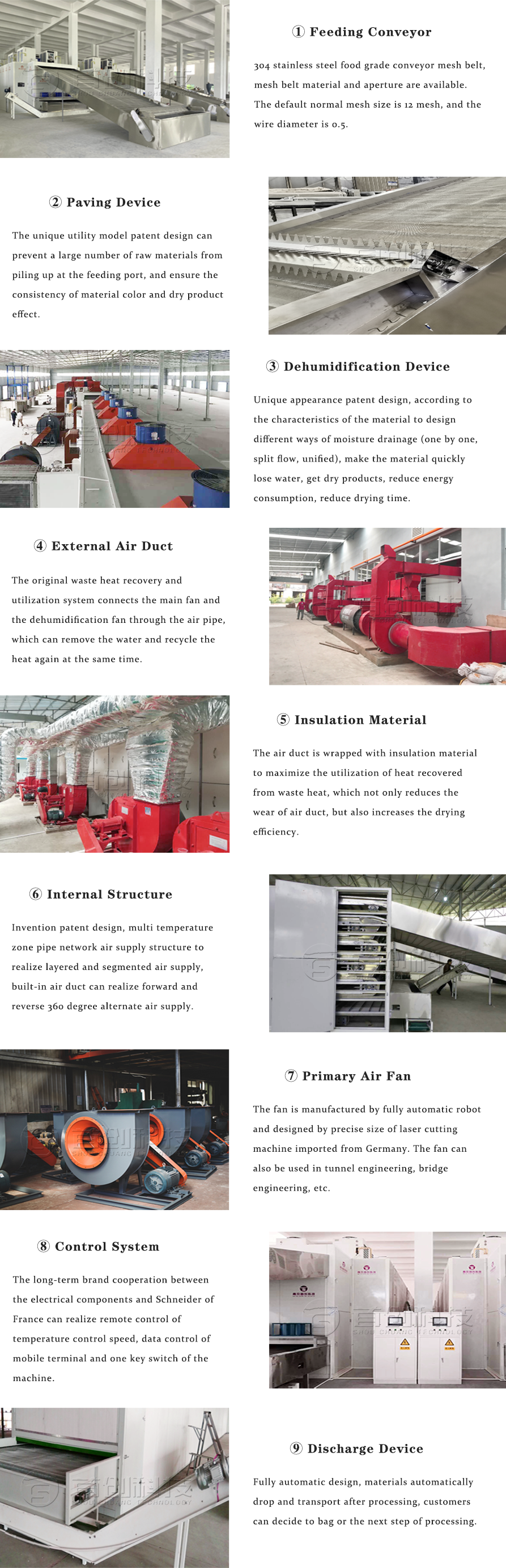

The konjak dryer is an automatic assembly line equipment. After the konjac is picked from the ground, it enters the cleaning machine for cleaning. This process needs to be repeated twice, and then let the konjac enter the slicing equipment on the top of the dryer through the elevator, and then enter the drying room for drying.

In the drying process of konjac, the heat provided by the heat source blows the hot air into the drying room through the heat exchanger, so that the temperature in the drying room will quickly rise to the temperature suitable for the drying of konjac and fix the color of konjac.

1.Heat exchange furnace.

2.Heat exchange furnace draft fan with chimney.

3.Fan (own brand fan).

4.Chili drying equipment system (Food grade stainless steel,drying temperature 30~160 degree centigrade).

5.Feeding conveyor.

6.Discharge conveyor.

7.Control panel.

8.Remote control temperature and humidity control system.

Choose us Choose Professional

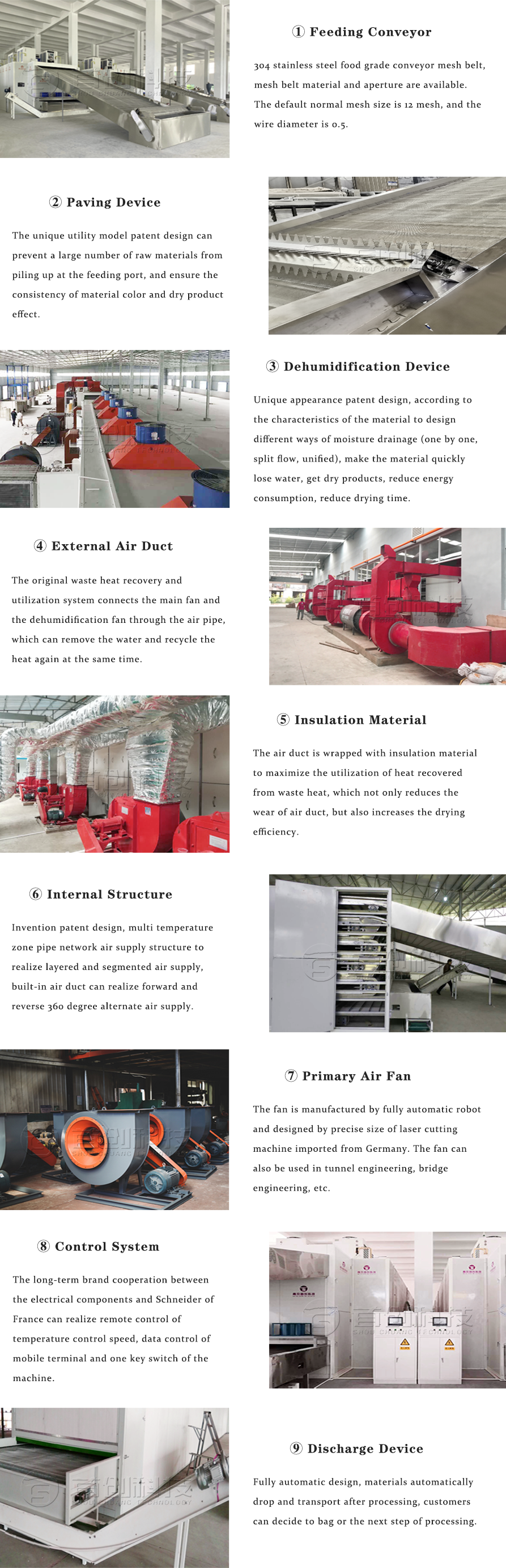

The konjak dryer is an automatic assembly line equipment. After the konjac is picked from the ground, it enters the cleaning machine for cleaning. This process needs to be repeated twice, and then let the konjac enter the slicing equipment on the top of the dryer through the elevator, and then enter the drying room for drying.

In the drying process of konjac, the heat provided by the heat source blows the hot air into the drying room through the heat exchanger, so that the temperature in the drying room will quickly rise to the temperature suitable for the drying of konjac and fix the color of konjac.

1.Heat exchange furnace.

2.Heat exchange furnace draft fan with chimney.

3.Fan (own brand fan).

4.Chili drying equipment system (Food grade stainless steel,drying temperature 30~160 degree centigrade).

5.Feeding conveyor.

6.Discharge conveyor.

7.Control panel.

8.Remote control temperature and humidity control system.

Choose us Choose Professional