- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

|

|

Supply Ability 350 Set/Sets per Year

Packaging Details Carton or Wooden case

Port Shanghai, Tianjin, Ningbo or other

Lead Time:

| Quantity(Sets) | 1 - 5 | >5 |

| Est. Time(days) | 30 | To be negotiated |

High quality vegetable food mushroom dryer

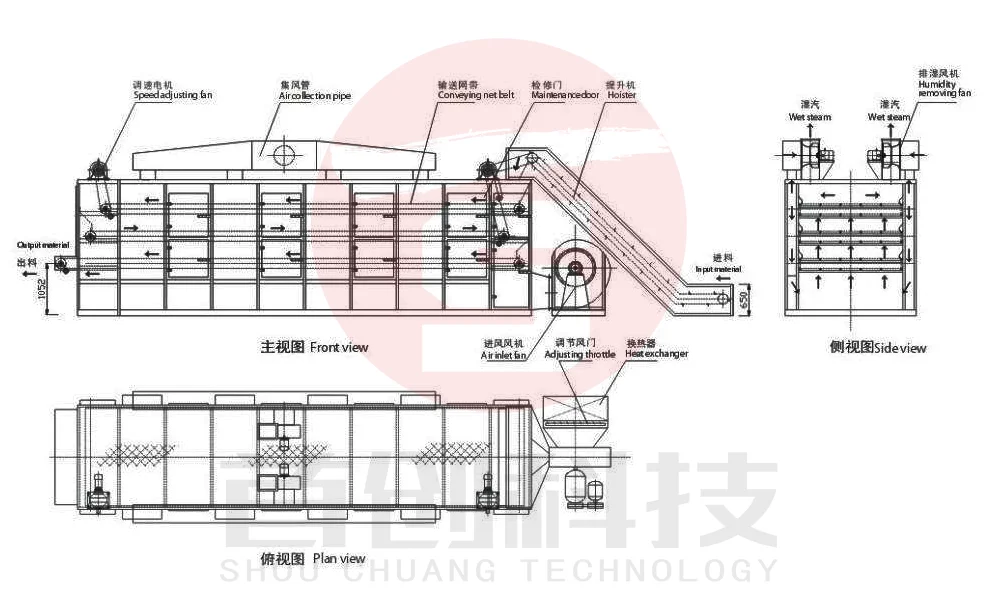

1.Heat exchange furnace.

2.Heat exchange furnace draft fan with chimney.

3.Fan (own brand fan).

4.Chili drying equipment system (Food grade stainless steel,drying temperature 30~160 degree centigrade).

5.Feeding conveyor.

6.Discharge conveyor.

7.Control panel.

8.Remote control temperature and humidity control system.

9.Corollary equipment

1.Advanced heat source system

Media for drying is pollution-free and completely food safety hazards, which is energy-saving and eco-friendly.

2.original dual mode of pule air suply technology

The drying uniformity is about 99%,and the drying cycle is greatly shorten by about 17 hours.

3.Advanced temperature control technology

Achieving precise temperature control by stages. For example, the air supply temperature of each stage can be set independently according to the requirement of drying materials as well as time setting. Ensure that the berry dry uniformly, keep their color ruddy and consistent, maintain their moderate skin fold and good taste.

4.Normal trays.

According tothe characteristics of berry, we design special material feeding wagons and material plates to avoid sticking,breaking, to keep the shape of berry.

5.High compatibility

Different drying process paramaterials can be set according to the drying process of various material to meet the high quality drying of various materials.

| Model | SC-HG180 | SC-HG270 | SC-HG430 |

| Layer | 6 | 6 | 6 |

| Paving thickness | 300m2 | 480m2 | 605m2 |

| Drying temperature | 30-160℃ | ||

| Drying cycle | 1-12 hours | ||

| Dehumidification intensity(kg/24h) | 9800-13500 | 13500-16700 | 16700-20580 |

| Total power of fan(kw) | 15 | 15 | 18.5 |

| Total power(kw) | 32 | 46.8 | 62.9 |

| Dimension(m) | 12*5.25*4.02 | 15*5.25*4.02 | 18*5.25*4.02 |

ShouChuang Technology is China's leading provider of agricultural product drying solutions and

is a state-level high-tech enterprise. Its predecessor was the Nanchong Drying Equipment Research

Institute of Sichuan Province. It has a history of more than 45 years of professional drying

equipment development.

The company has a complete database of agricultural product drying processes, providing the

industry's most complete product line and drying solutions, flexibly meeting the differentiated

needs of different customers and the pursuit of rapid innovation.

|

|

Supply Ability 350 Set/Sets per Year

Packaging Details Carton or Wooden case

Port Shanghai, Tianjin, Ningbo or other

Lead Time:

| Quantity(Sets) | 1 - 5 | >5 |

| Est. Time(days) | 30 | To be negotiated |

High quality vegetable food mushroom dryer

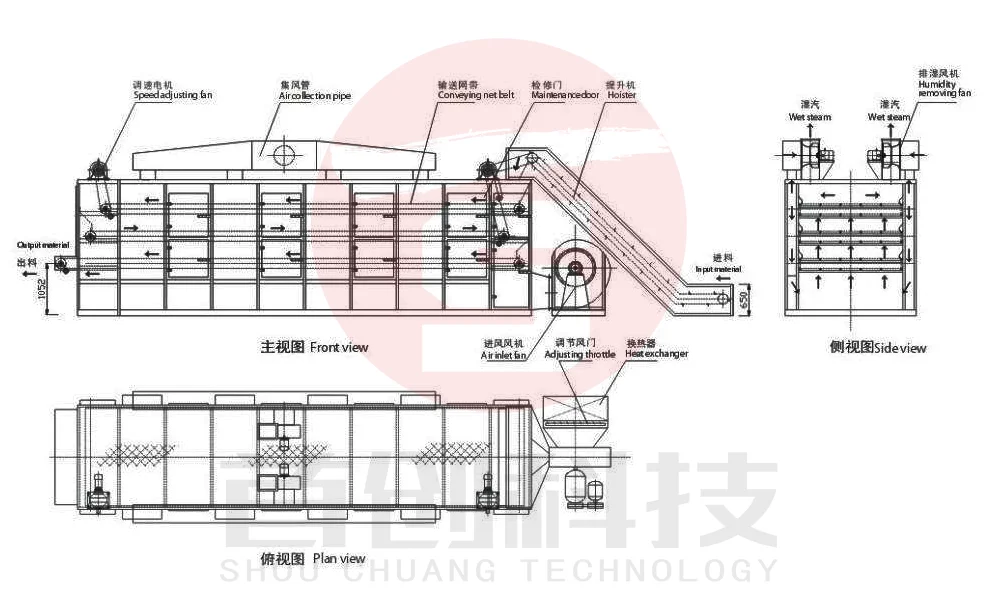

1.Heat exchange furnace.

2.Heat exchange furnace draft fan with chimney.

3.Fan (own brand fan).

4.Chili drying equipment system (Food grade stainless steel,drying temperature 30~160 degree centigrade).

5.Feeding conveyor.

6.Discharge conveyor.

7.Control panel.

8.Remote control temperature and humidity control system.

9.Corollary equipment

1.Advanced heat source system

Media for drying is pollution-free and completely food safety hazards, which is energy-saving and eco-friendly.

2.original dual mode of pule air suply technology

The drying uniformity is about 99%,and the drying cycle is greatly shorten by about 17 hours.

3.Advanced temperature control technology

Achieving precise temperature control by stages. For example, the air supply temperature of each stage can be set independently according to the requirement of drying materials as well as time setting. Ensure that the berry dry uniformly, keep their color ruddy and consistent, maintain their moderate skin fold and good taste.

4.Normal trays.

According tothe characteristics of berry, we design special material feeding wagons and material plates to avoid sticking,breaking, to keep the shape of berry.

5.High compatibility

Different drying process paramaterials can be set according to the drying process of various material to meet the high quality drying of various materials.

| Model | SC-HG180 | SC-HG270 | SC-HG430 |

| Layer | 6 | 6 | 6 |

| Paving thickness | 300m2 | 480m2 | 605m2 |

| Drying temperature | 30-160℃ | ||

| Drying cycle | 1-12 hours | ||

| Dehumidification intensity(kg/24h) | 9800-13500 | 13500-16700 | 16700-20580 |

| Total power of fan(kw) | 15 | 15 | 18.5 |

| Total power(kw) | 32 | 46.8 | 62.9 |

| Dimension(m) | 12*5.25*4.02 | 15*5.25*4.02 | 18*5.25*4.02 |

ShouChuang Technology is China's leading provider of agricultural product drying solutions and

is a state-level high-tech enterprise. Its predecessor was the Nanchong Drying Equipment Research

Institute of Sichuan Province. It has a history of more than 45 years of professional drying

equipment development.

The company has a complete database of agricultural product drying processes, providing the

industry's most complete product line and drying solutions, flexibly meeting the differentiated

needs of different customers and the pursuit of rapid innovation.